Metallurgy

Global economic expansion has greatly increased the demand for iron, steel, aluminum, and copper. Scrap handling facilities, steel plants, rolling mills, aluminum smelters, and electrowinning operations require rugged material handling machines that place high demands on energy and data transmission systems. Reliability is of paramount importance, as any unscheduled downtime will cause waste and lost productivity. Electric systems must withstand high heat, sparks, metal splatter and conductive dust. Aluminum pot line cranes need conductor systems that can handle high currents during the stationary operating cycle. In steel mills, mission-critical charging and ladle handling cranes must operate where furnaces and molten steel ambient heat often exceeds 70°C. To survive, cables need special heat shielding and conductor rails often require high-heat insulation. Bar, billet and coil handling cranes operate at high speeds and must position and turn loads accurately. Lastly, the environment around electrowinning and plating lines will corrode ordinary electrification components.

Conductix-Wampfler products are used in metals facilities all over the world. We understand metallurgical processes from raw material supply, to metal making, to final finishing. With our global sales and service network, we are always close to your business for local service and support. If you need on-site installation assistance or a complete turnkey-job, there is no more experienced partner than Conductix-Wampfler.

Our products for metal plants include:

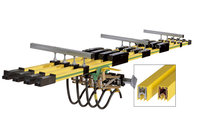

Conductor Rails – provide runway power for Charging Cranes, Ladle, and Tundish Cranes, slab/billet cranes, and coil/bar/plate handling cranes. Insulated bars are used up to 1500 amp; Welded Cap Rail for 2500 to 6000 amps. They power cranes in corrosive sintering, plating, and electrowinning operations, with optional Dura-Coat protection and supply continuous current draw for aluminum pot line cranes that operate while stationary.

Cable Festoon Systems – reliable cable handling for bridge power to all process and handling cranes with straight or curved runs. Our optionally pre-assembled systems minimize installation time.

Motor-Driven Reels – are low maintenance and manage cables and hoses for transfer cars, dependably.

Spring-Driven Reels – provide power for scrap crane magnets and other uses.

Energy Guiding Chains – manage cables and hoses for various types of moving equipment.

Slip Ring Assemblies – with rugged enclosures, transfer power and control signal to rotating ladle turrets on continuous casters or provide rotating control/power for pot line cranes.

Jay Radio Remote Controls – offer a safe way of operating or monitoring machines from a distance. The comprehensive range of industrial and safety radio remote controls offers countless solutions to adapt to an extensive number of metallurgy applications.

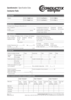

-

Hot Metal Process Crane in a Powder Metal Plant

Reference Report

[REF0514-0004-EN]

Hot Metal Process Crane in a Metal Powder Plant

Application

Hot Metal Overhead Crane

Country

Sweden

Project installation date

2017

Representative office

Conductix-Wampfler AB [SE]

Customer

BANG Kransysteme | Germany

Operator

Höganäs Sweden AB | Halmstadt | Sweden

Technical requirement[s]

Energy sypply and data transmission to one overhead crane with Conductor Rails and ProfiDAT®

[ProfiNet data transmission / Real-time data transmission to the crane PLC]

Travel length [Crane bridge]

95 m

Travel speed [Crane bridge]

60 m/min

Crane loading capacity

75 t / 25 t / 6,3 t

Product[s]

• ProfiDAT®, Program 0514

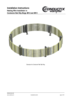

• Aluminum Conductor Rail, Program 0813 SingleFlexLine with standard PVC insulation up to +55 °C

• Aluminum Conductor Rail, Program 0813 SingleFlexLine with PPE insulation for ambient temperatures up to +85 °C

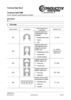

Current Collector

• ProfiDAT® current collector with protective earth carbon brush and data transmission antenna

Additonal product information

• ProfiDAT® for grounding and data transmission

• PPE insulated conductor rail segments are installed in the areas with the highest ambient temperature. Additional steel plates shield the conductor rails and ProfiDAT® profile from the radiation heat

Relevant Products

ProfiDAT®

Additional information

ProfiDAT® is a contactless data transfer solution for communication between fixed and mobile control units from Conductix-Wampfler. ProfiDAT® makes it possible to achieve reliable transfer of mixed data (video, audio and real-time control) at very high data rates using Conductix-Wampfler slotted waveguide technology. Data can be safely transferred at rates up to 100 Mbit/s with average latency of only 3ms. The unique configuration of waveguide and mobile antennas results in a system with integrated shielding. This isolation means that ProfiDAT® is license free and can safely transfer data, even in the most challenging radio environments (e.g. shipping container terminals).

ProfiDAT® is excellently suited for integration into conductor rail systems because the waveguide profile has been engineered for dual use as the protective earth (PE) conductor rail. This results in a very compact complete system because an additional PE conductor rail is not required. The ProfiDAT® data transfer system can be combined with multiple available Conductix-Wampfler conductor rail systems.

Main Applications

- STS Crane (Ship-to-Shore)

- RTG/E-RTGTM Crane (Rubber-Tired Gantries/ Electrified Rubber-Tired Gantries)

- Process Crane

Key Features

- Safe and reliable wireless communication using slotted waveguide technology

- Real-time data transfer through prioritization of PROFINET data packets

- PROFIsafe compatible

- Solutions for expansion joints and separation points

- Cost saving through dual use of ProfiDAT® as communication channel and protective earth (PE) conductor rail

- Compact and fully integrable into conductor rail systems

Product data

Standard Application Data

- Data rate [Mbit/s]:up to 100

- Real-time capable: Yes (PROFINET)

- Average latency [ms]: 3

- Maximum distance (without repeater) [m]: 500

- Safe communication: Yes (PROFIsafe)

- Dual use as protective earth (PE): Yes

- Multiple mobile units in one profile possible: Yes

- Profile section length [mm]: 5.000

- External dimensions (profile) [mm]: 50 x 56

- Suitable for indoor and outdoor applications: Yes

- Temperature range [°C]: -25 bis +50

Downloads

Single PowerLine 0813

Additional information

Single pole conductor rail preferably for straight tracks

Special features

- Available with different rail materials, suitable for most industrial environments

- High safety level due to integrated finger-safe design

- Easy and exact mountig with multiple hanger clamps for 3, 4 and 5 poles

- Unlimited number of poles, designed for complex systems

- Curved segments available

Main applications

- Process and EOT cranes

- People movers

- Container cranes

Product data

Standard application data

- Nominal Current (at 100% duty cycle) [A]: 500 | 800 | 1.000 | 1.250

- Voltage Grade [V]: 690

- Rail Length [mm]: 5.000 [16.40 ft]

- External Dimensions (Pole) [mm]: 32,0 x 42,0 [1.26" x 1.65"]

- Operating Conditions: for indoor and weather-protected outdoor applications

- Track Configuration: preferably for straight tracks / curved segments available

Downloads

Installation Instruction

Conductix-Wampfler GmbH

Merkezi Almanya Türkiye Şubesi

Istanbul

İMES Sanayi Sitesi

C-308 Sokak No:19

Dudullu OSB/Ümraniye

Turkey

Phone: +90 216 511 58 64

www.conductix.com.tr

info.tr@conductix.com

- 2 more clicks for privacy: By clicking here, the button becomes active and you can send your recommendation to Facebook. With the activation data will be transmitted to third parties.mit Facebook verbunden

- 2 more clicks for privacy: By clicking here, the button becomes active and you can send your recommendation to Twitter. With the activation data will be transmitted to third parties.nicht mit Twitter verbunden